solid bronze bearing with graphite lubricating

- Brand JSP

- Type JDB

JDB bearing - Solid-lubricant bronze bearing bushing

- Introduction

1.The solid bronze/iron material is ideally suited for highly demanding applications in tough environments. We offer a standard assortment of plain sleeve bushings, flanged bushings and sliding plates in accordance with ISO 4379 and DIN1850.

2.The solid bronze body can be drilled holes and filled solid graphite lubricant, in this way it can be used in oilless environments.

3.Also the solid bronze body can be machined oil grooves and holes, it can get better lubricating after filled with grease.

- Features and advantages

1.Insensitive to dirty environment

2.Resistant to shock loads and vibrations at slow speeds

3.Enable operation with a poor shaft surface finish

4.Good resistance to corrosive conditions

- Material

Solid Bronze bushings and plates are made completely of tin bronze, CuSn10P, which has very good machine ability. All surfaces of the solid bronze bushings are machined.

Solid iron bushings and plates are made in same way of bronze material, but it is much lower costs if you are not in high performance requirements.

- Examples of applications

1.Construction machinery

2.Transport equipment

3.Pulp and papermaking machinery

4.Off-shore equipment

- Specifications:

|

Material |

Bronze |

CuZn25Al6Fe3Mn3 + Graphite |

|

Iron |

Cast-iron + Graphite |

|

|

Density |

|

8.2g/cm3 |

|

Tensile Strength |

|

>=755N/mm2 |

|

Anti-compact Tenacity |

|

>=400~500KJ/m3 |

|

Hardness |

|

>=200HB |

|

Max Load Pressure |

|

100N/mm2 |

|

Speed Limit |

|

0.5m/s |

|

PV value limit |

|

1.65N/mm2.m/s |

|

Friction coef |

Oil Lubrication |

0.03 |

|

Dry Friction |

0.16 |

|

|

Working temperature |

|

-40~+300°C |

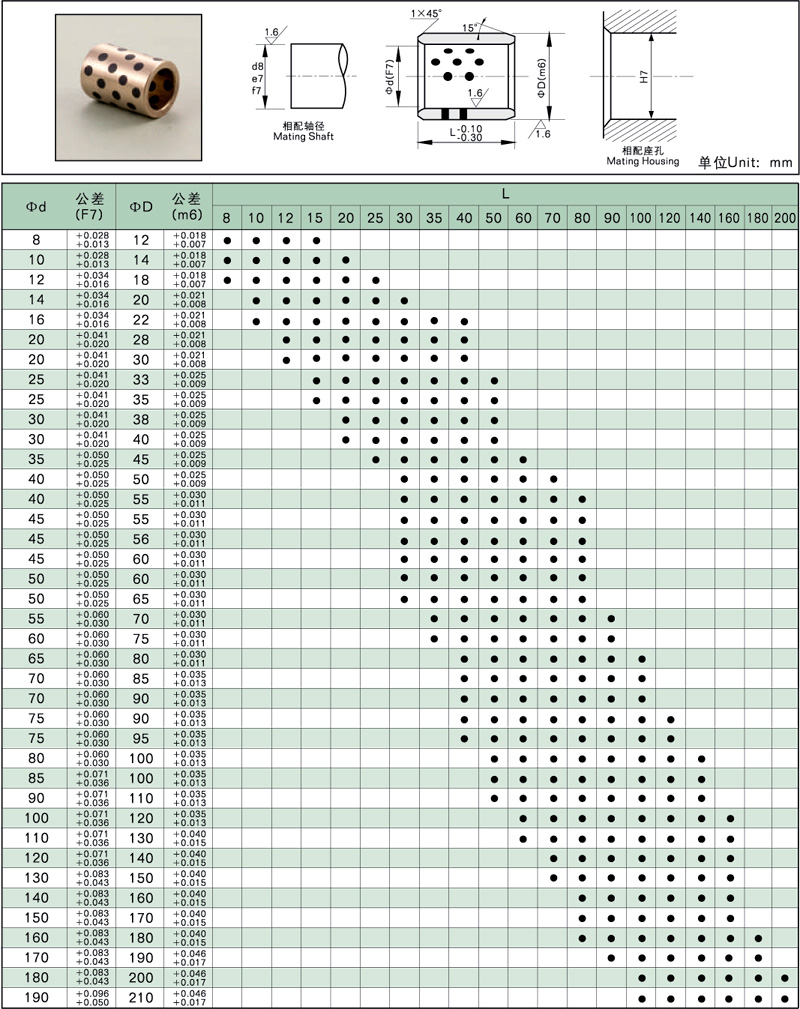

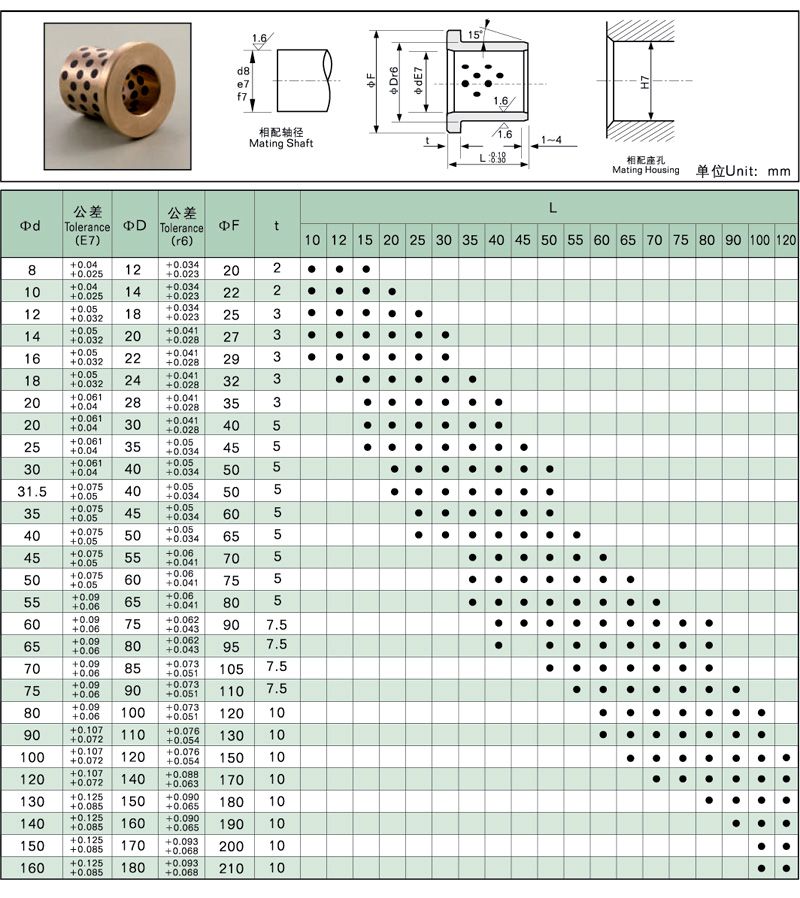

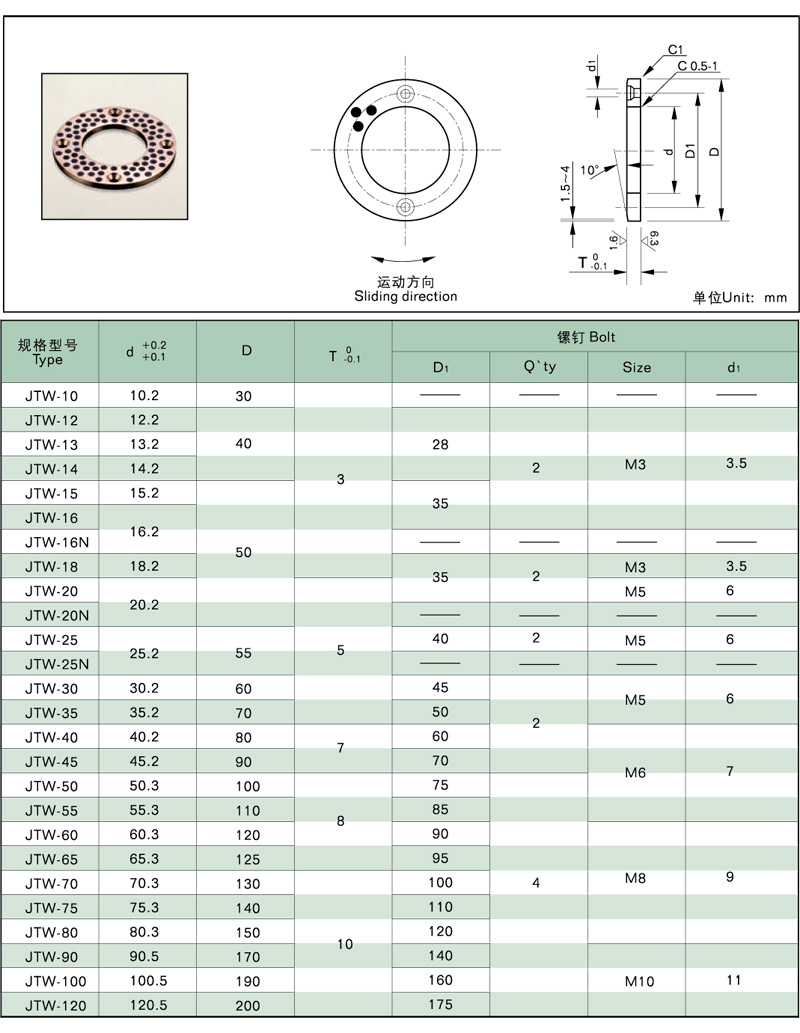

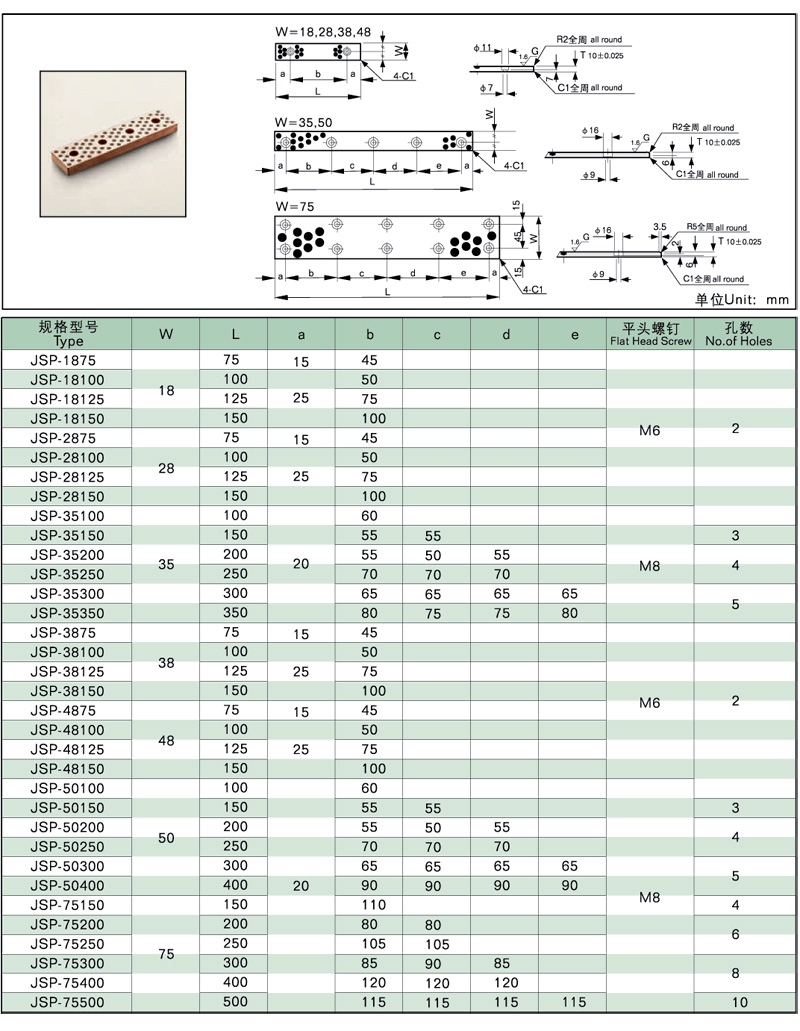

- Types and sizes list:

1.Sleeve

2.Flanged

3.Washer

4.Sliding plate

- Plant

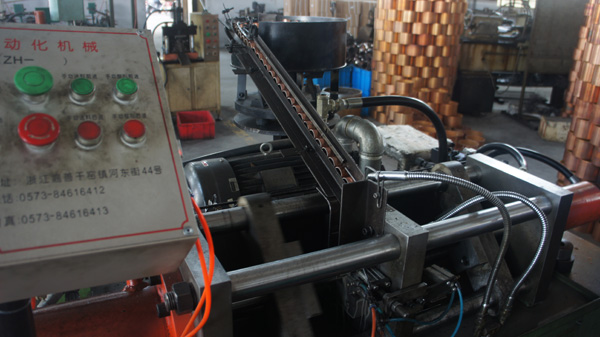

- Production Line

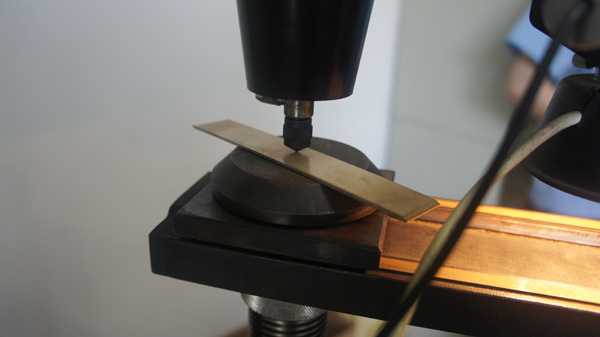

- Inspection

- Packings:

In the same category

-

Marine Bronze bearing SL4

-

hatch cover bronze bushing pad in ptfe lubricant lubripad

-

white ptfe solid lubricant type bushing,bearing supplier,wear plate,pad

-

plugged graphite bushing,plugged graphitebearing , graphite plugged bronze bearing

-

spherical bronze bushing with graphite

-

oilless bearing,oiles bearing,self lubricating bearing supply

-

oilless bearing,oiles bearing bronze

-

PTFE graphite bronze bushing, water graphite bronze bushing

-

bronze wear oval washers

-

casting bronze graphite material sliding pad

-

JWB bronze washers with graphite dots

-

JDB solid bronze bearing

-

oilless slide plate,wear plate, graphite plugged plate

-

Cast thrust washer-bronze graphite bushing

-

PTFE bronze bushings,PTFE+graphite lubricating,white lubricant

-

JDB Iron graphite bushing

-

JFB bronze graphite sliding bearing

-

JPB bronze graphite plate pads

-

Cast Iron bronze bearing for auto parts solid lubricant inlaid bearing

-

Self-Lubrication Wholesale Custom Anti-Friction Casting Bronze Bushing

-

Custom Self Lubrication Graphite Cast Bronze Bushing Oilless Bearing

« PTFE graphite bronze bushing, water graphite bronze bushing bronze wear oval washers »