YT rail soft belt to eliminate crawling, prevent wear and ensure fast, accurate and balanced operation.

MATERIAL INTRODUCTION

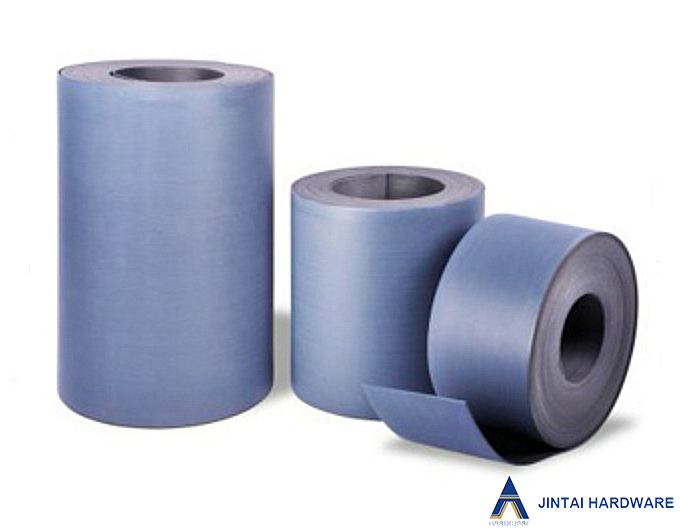

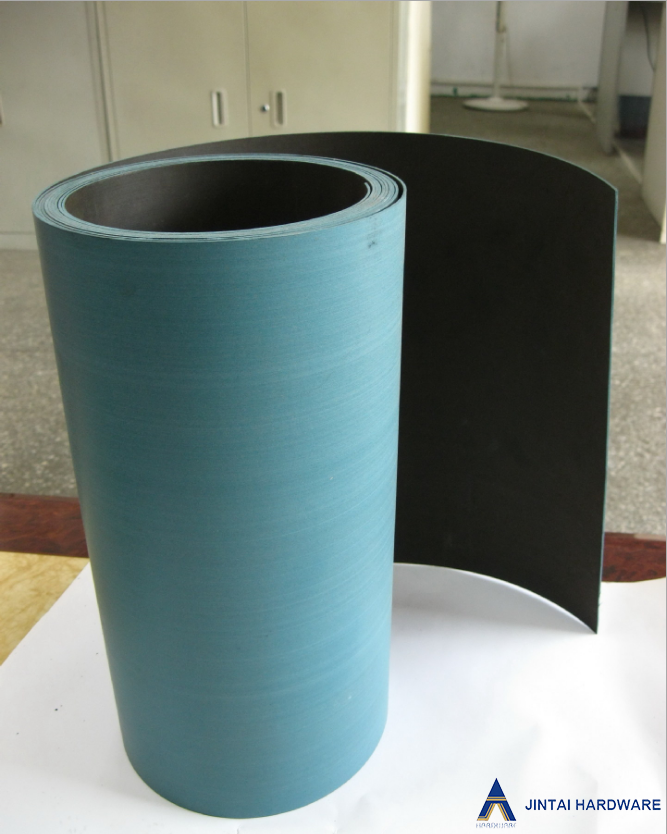

01 YT Soft Tape for Guide-way, a kind of turning soft Tape made of PTFE, filled, modified, and surface

activated, has excellent friction and wear-resistance characteristic and almost same static and dynamic

friction coefficients. As a kind of novel material, it can be used in the manufacturing and repairing of machine tools, especially can be used as the guide way's abrasion-proof surface on precision machine tools

02 Machine tools equipped with the YT soft tapes can avoid the crawling phenomenon effectively, avoid abrasion to guide set,locate exactly quickly and move smoothly for sure; and will produce no tremor.

03 YT guide soft tape can also be used as a self-lubricating, wear-resistant sliding bushing/gasket, which is easy to use with good wear resistance.

MATERIAL PROPERTIES

01 With almost the same static and dynamic friction coefficients, it can avoid crawling phenomenon, canoperate smoothly, and has good fretting position performance.

02 With excellent abrasion resistant property , it can strengthen the stability of guide-way accuracy , and prolong the machine tool's maintenance period.

03 With shock absorption and sound absorption performance, it can enhance the processed parts' surface accuracy and quality.

04 With good self-lubricating property and small friction coefficient , it can reduce driving force consumption, and avoid the scratching on metallic guide way surface.

05 For can be maintained easily , it can be used in the renovation and repair of abandoned machine tools.

TYPICAL APPLICATION

01 With almost the same static and dynamic friction coefficients, it can avoid crawling phenomenon, canoperate smoothly, and has good fretting position performance.It could be used in manufacturing and maintenance of the sliding guide-ways on various precision, NC, and heavy duty machine tools and on textile and printing machinery.

TYPICAL APPLICATION

PRODUCT SPECIFICATIONS

ADHESIVE BONDING TECHNOLOGY

Generally, YT soft tape will be affixed to the sliding guide way's assistant short guider, and will slide together with the long guide way. Clear away the rust and oil on the metallic guide's sticking surface, clean it with acetone solution, and then air it. Before stick a YT soft tape to a metallic guide way, please keep the finishing degree (Ra) of the metallic guide's sticking interface in the range 6.3-12.5μ m, and assure it is little narrower to its matching guide way.

Special adhesives manufactured by our company are available,and please refer to their instructions for the detailed production process.

To apply the adhesive, please smear it longitudinally and homogeneously with short-hair brushes or strickles with teeth on the metallic sticking interface, and laterally on the YT guide soft tape's sticking interface (a grey surface). It shall not be too thinner or too thicker, generally the cured adhesive layer can be changed from 0.08 to 0.12 mm.

Please press and flatten the YT guide soft tape well to let it fully contact with the guide way's surface, before sticking it to avoid air bubbles or other bad contact phenomenon. For large/middle size machine tools, before sticking the YT tape, please fix its two ends with platens or screws on the guide way's surface.

The guide way with an adhesive YT soft tape, shall cure under pressure in room temperature or under heating condition, it can be pressurized reversely using the machine tool table's weight, and the pressure applied on it must be uniform. If necessary, laying weight objects to increase pressure 1Kg per cm² .The guide way's surface with cured adhesive and the YT soft tape can be processed by mechanical machining or manual scraping to reach its anticipative precision.To help our customer use YT soft tape effectively and reasonably, we have started a service for YT soft tape sticking operation, assigning specialists to give directions or operate the work.

THE FRICTION COEFFICIENT

As a basic structural element of a machine tool, to a large extent,the machine tool guide's quality will decide the machine tool's precision and lifecycle. The most common machine tool guides are made of cast-iron, whose friction coefficient is large and varies greatly along with the relative sliding speed; So, easily, they will bring crawling (or stick-slip) phenomenon, which will affect the machine tool's precision, and the processed parts'quality badly.

« COM high-strength cloth phenolic semi-finished products (pipe) FPG fluorocarbon guide belt »